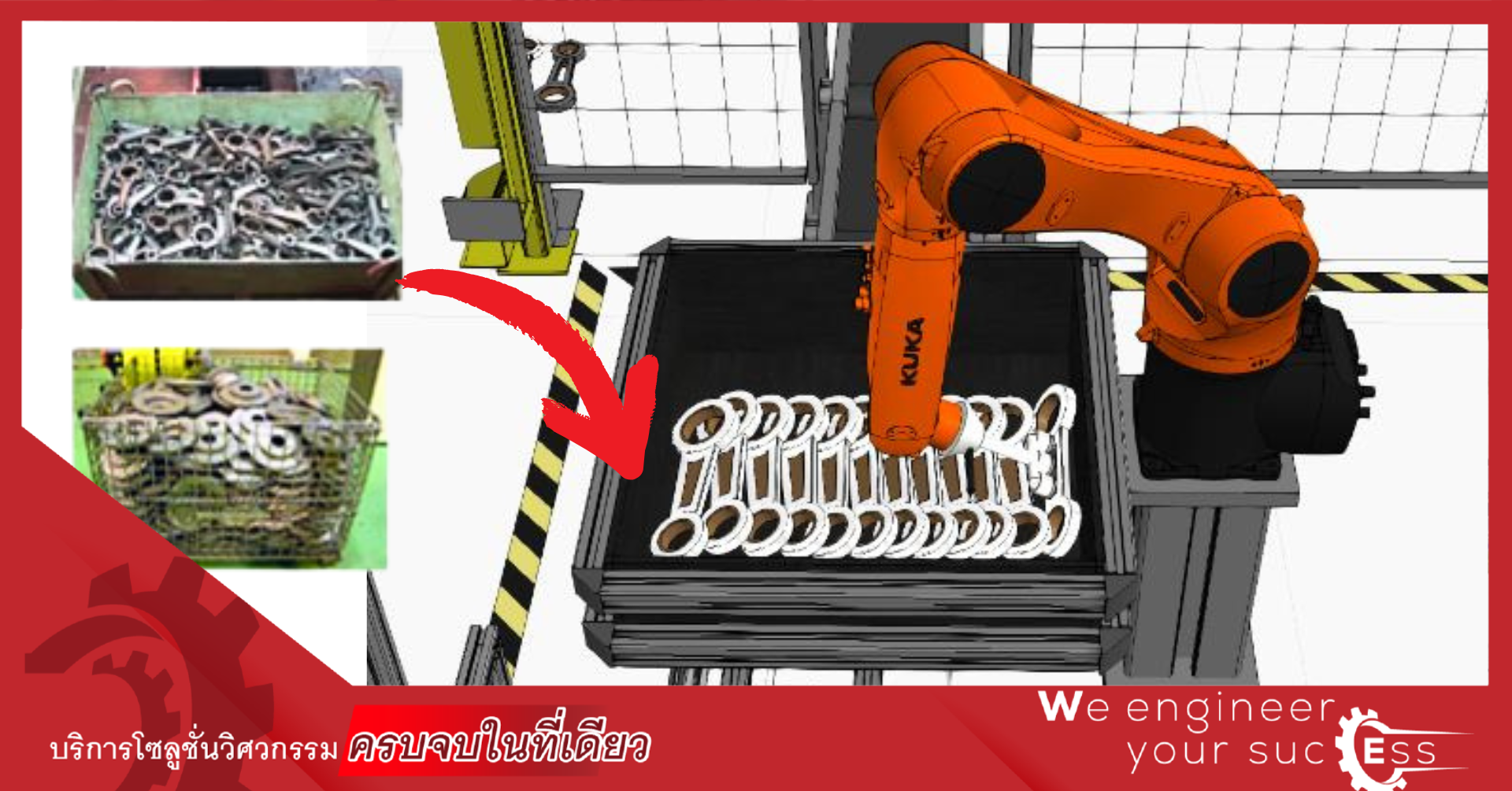

In today’s changing work environment and market demands, where there’s a shortage of workers and a growing need for automation to handle products faster and more safety for production line, West Coast Engineering Company Limited has developed The Pick and Place robot systems. These systems, equipped with 3D camera positioning, automatically adjust to meet customer needs.

The Pick and Place robotic automation system is designed for flexibility, cutting down on the need for mechanical components. The 3D camera integration makes it easy to operations, streamlining the workflow for collaborative robot systems.

This not only saves on operating costs but also reduces expenses for modifying jigs and fixtures when changing product models, ultimately boosting overall efficiency.

KEY BENEFITS

- Reduced Cost : Fully Autonomous Process

- Easy Model Change : No Mechanical Jig & Fixture

- Easy Teaching : User friendly Vision Software with Cad Based and AI

- Fast installation and Commissioning Flexible : Minor Mechanical Component

- Workforce Reduction : Reduce 2-3 workers in part alignment process and working process

COMMON INDUSTRIES

✅ Automobile Factory

✅ Semi-conductor producers

CELL OPTIONS

- Grippers: Custom Design

- Safety : Laser scanner, Safety fence & light curtain

- 3D Vision : Part Location and classification

- Electrical Control : HMI & PLC

Are you struggling with picking objects from a bin that are either randomly placed or have different shapes and sizes?

West Coast Engineering Company Limited (WCE)

🌐 www.wce.co.th

✉️ international@wce.co.th

📞 +66 (0) 65-9376283

Your Turn Key Engineering Solution

We engineer your sucCEs