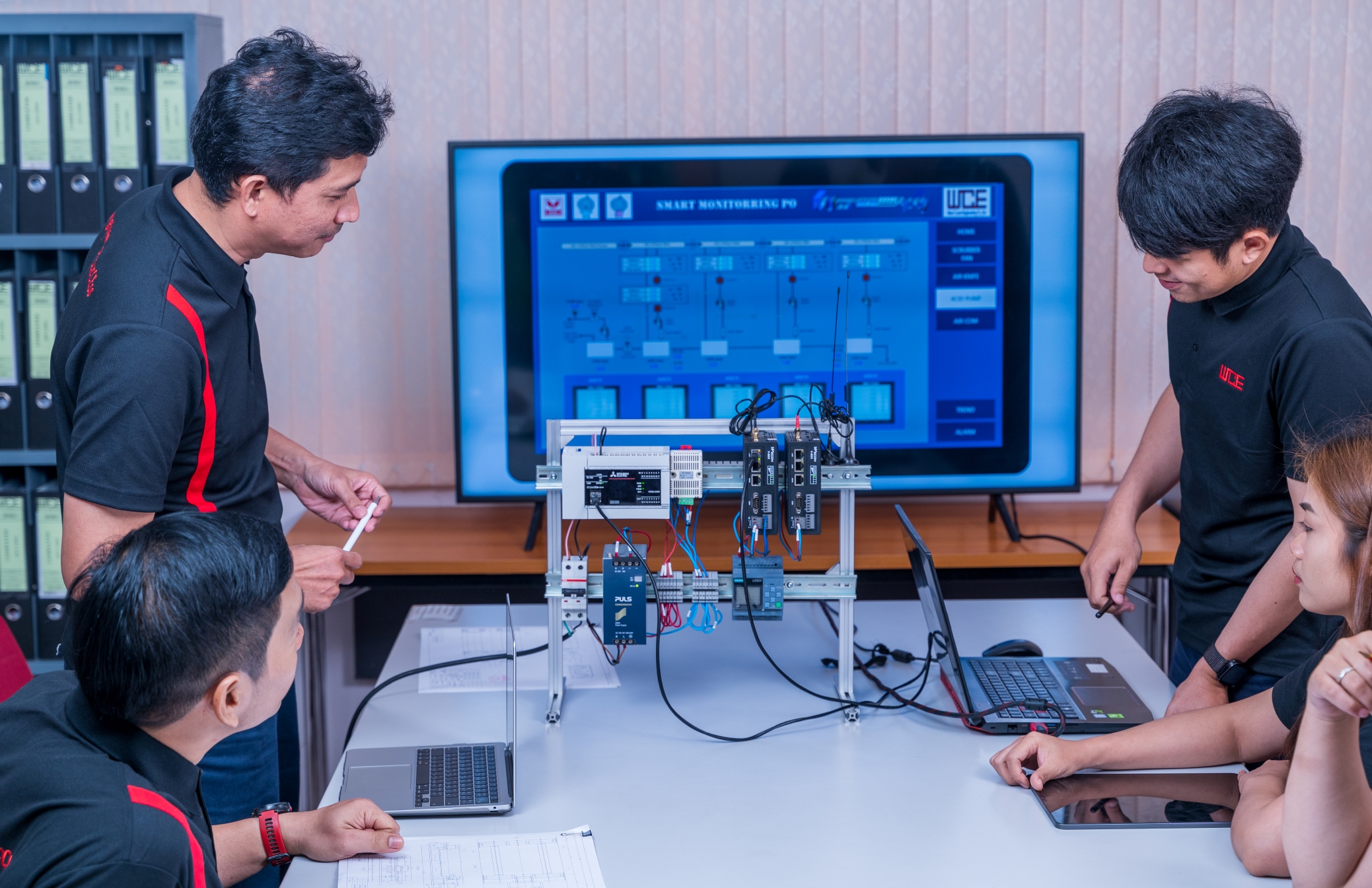

Our solutions cover the entire process, from engineering design and procurement to installation, testing, and user training, ensuring effective operation.

Our solutions cover the entire process, from engineering design and procurement to installation, testing, and user training, ensuring effective operation.

We provide industrial automation solutions for various industries, including steel and automotive sectors, total automated warehouse solutions include material handling and welding robotics systems.

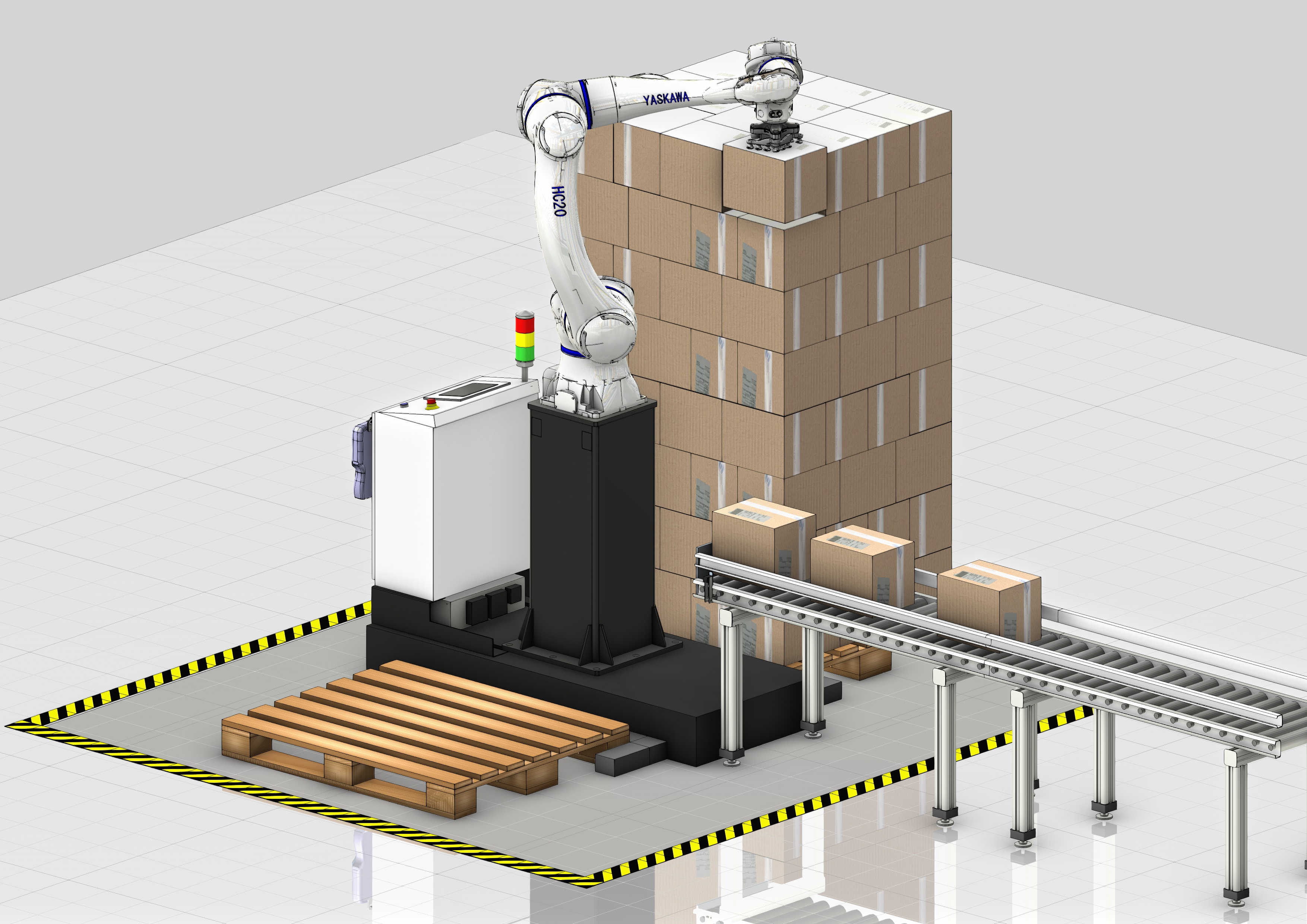

Our automated warehouse solution provide Warehouse management system with innovative solutions

such as ASRS Racking, Automated Stacker Crane System, Conveyor and Sorter System including Handling Robot System

Our services help you improve your work efficiency, reduce costs and time, are easy to use, and can be customized with specific experience and expertise.

The services provided by RAT unit cover the entire process from engineering design, procurement, installation, testing, to user training, with comprehensive solutions capable of meeting diverse needs, along with advanced security systems. with over 20 years of high-level expertise.

Design and install comprehensive industrial automation systems to address operational challenges and improve efficiency. This includes the addition of new systems or integration with existing systems and improve efficiency by modifying or upgrading existing automation systems.

Design and install automated testing machines for automotive component products. These machines can be semi-automated or fully automated and undergo stringent quality testing certified to IATF16949, meeting customer specifications.

our service offer comprehensive solutions to solve issues and boost your warehouse capabilities. including building structures, engineering design, and automation system installations to conveyor systems and performance testing, providing a complete solution for automated warehouse construction.

Automated Warehouse Solutions include:

– Automated Storage and Retrieval System (ASRS Racking)

– Automated Stacker Crane System

– Conveyor and Sorter System

– Warehouse Management System (WMS)

– Handling Robot System

Design and install robots that arrange lightweight products in low-light conditions. These robots utilize sensor and camera technology for detection, working in various lighting conditions. They are compact and low-profile, requiring minimal installation space.

Design and install robots that pick and place objects from uncertain positions using 3D camera technology. They can work in a variety of environments, handling complex and differently sized objects without the need for prearrangement.

Design and install robots that automatically find and weld seams using sensor technology for precise automatic seam tracking. This ensures high precision and consistent welds, reducing the need for reprogramming when welding new pieces.

A group of customers who have utilized our Robotic & Industrial Automation Service for over 20 years.

Chatchawat Saejung

Head of Robotics and Industrial Automation Solution and Service Business Unit

Sade Chaimongkon

Engineer of Robotics and Industrial Automation Solution and Service

Jittisak Watcharaburapanun

Engineer of Robotics and Industrial Automation Solution and Service

Purchasing Department : phaiboono@wce.co.th | Human Resources and Administration Department : hrmwce@wce.co.th | Sales Department : international@wce.co.th

16 K&Y Building 5 Fl., Surasak Road, Silom Sub-District, Bangrak District, Bangkok, 10500

Mobile Phone +66 (06) 5937 6283

Fax +66 (0) 2233 6669

9/1 Moo 4, BanKlangNa – YaiPloy Road, Maeramphueng, BangSaphan, PrachuapKhiriKhan 77140

Telephone +66 (0) 3290 6112 – 119

Fax +66 (0) 3290 6120