West Coast Engineering Company or “WCE” had revealed, according to had executed coal warehouse and conveyor project of SCG group. Which will have nearing completed, so that it to the right time Sahaviriya Steel Industry Public Company Limited or “SSI” had collaborated with WCE to increase strength. They had set automation system for manufacturers of SCG group between older machines system and new machine system.

Mr. Ratchata Jirachotekamjorn is the Assistant Vice President of group technology automation development of Sahaviriya Steel Industry Public Company Limited or “SSI” had revealed, according to the company had restructured organization for management and we had driven business direction onto the investment company focused be enough to cover investment. It is a great opportunity for employee to increasing their experience and expand for their job description. Ours employee should be extensive execution apart from only steel industry. Latest SSI had collaborated with WCE which was subsidiary in Sahaviriya Group. They had set automation system for manufacturers of SCG group. These include the Thai Cane Paper Public Company Limited or “TCP” and the Siam Kraft Industry Company Limited or “SKIC” which were subsidiary in Siam City Cement Group or “SCG Group”. The objective is to reduce the cost of hiring the outsource.

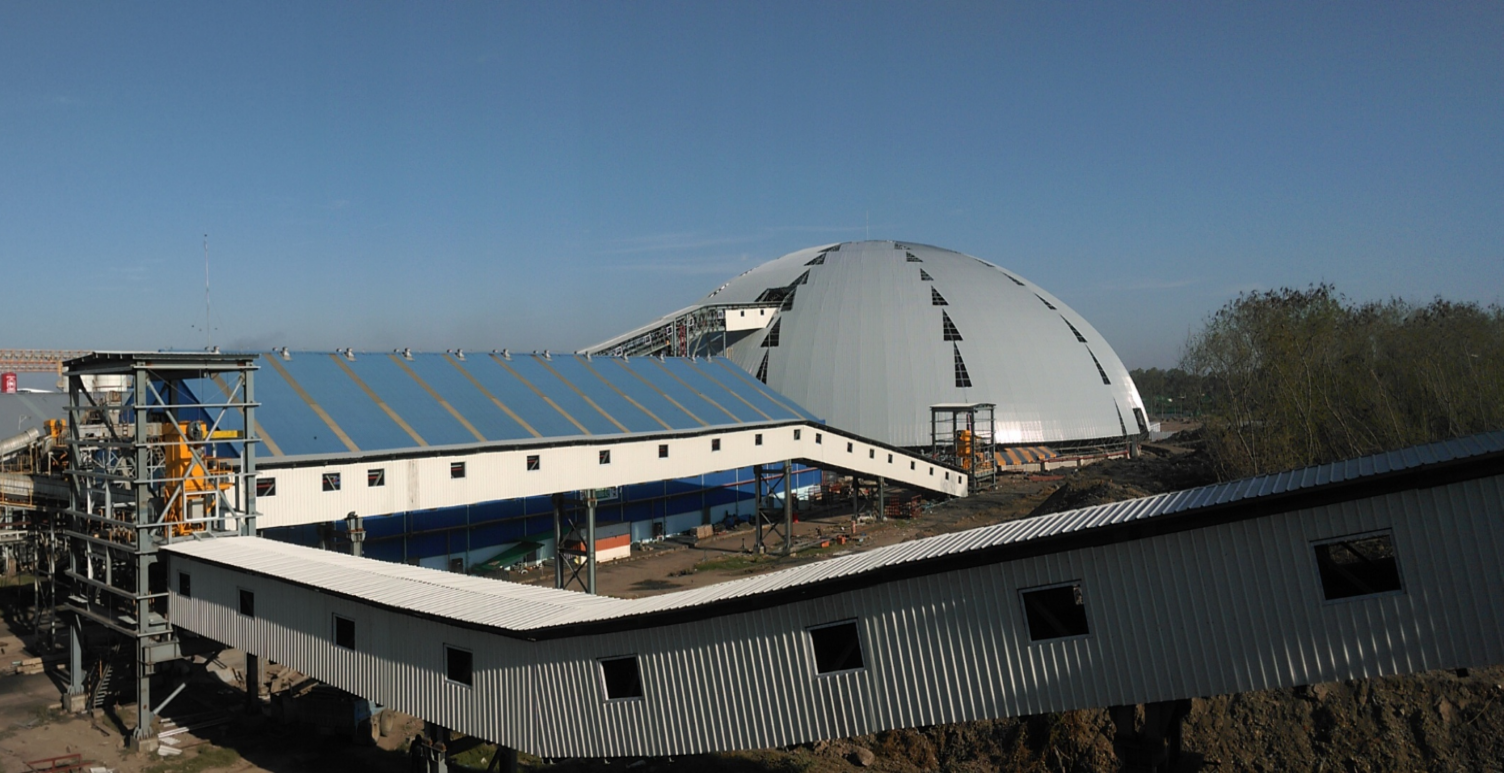

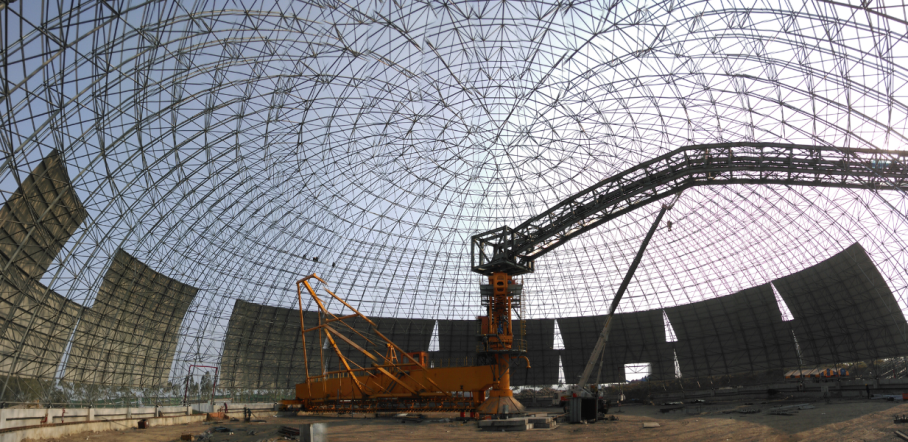

West Coast Engineering Company or “WCE” had revealed, Firstly had received purchase order from TCP for project “New coal warehouse” which scope cover construction the coal warehouse building have capacity 80 tons value amount 88.45 million baht and located at Ampor Wangsala Kanchanaburee province. Secondly WCE had received purchase order from SKIC for project “New coal warehouse” which scope construction coal warehouse and installation stack for belt conveyor which have capacity 30,000 tons. Located in line for steam and production value amount 180 million baht at Ampor Banpong ,Ratchaburee province.Likewise of the operations the two projects was SSI had set automation system only takes two months. Firstly, connection between the new machines automation system to the old machines automation system. Next, SSI was able to automatic execution under control from the fifth computers on mode “Full automatic”. In the other hand the original on mode “Manual”. Finally, SSI had set alarm mode especially in case had found abnormal in line production process.In fact to the manufacturing process are initial from coal conveyor system located at truck dumper. It are dumps the coal to go to inventory keep at coal dome warehouse. Next, the coal are transports by conveyor again to go to the boiler area of SKIC which the automation system conveyor control by Programmable Logic Controller or “PLC”. In addition to, Firstly auxiliary dust collector system used quantity fifth of PLC. Secondary, Dome warehouse system used quantity two PLC with accessory each of monitor type touch screen. All there had used to control coal scatter system and coal spread out system.

Mr. Ratchata Jirachotekamjorn had revealed, this operate job outside group industry must show about that the employee from SSI have high efficiency in automation system, in the other manufacturing processes. In the future SSI will have expanding the automation system to another group industry for worldwide.

Contact Us

West Coast Engineering Company Limited (WCE)

🌐 www.wce.co.th

✉️ international@wce.co.th

📞 +66 (0) 2234-9889

Your Turn Key Engineering Solution

We engineer your sucCEss