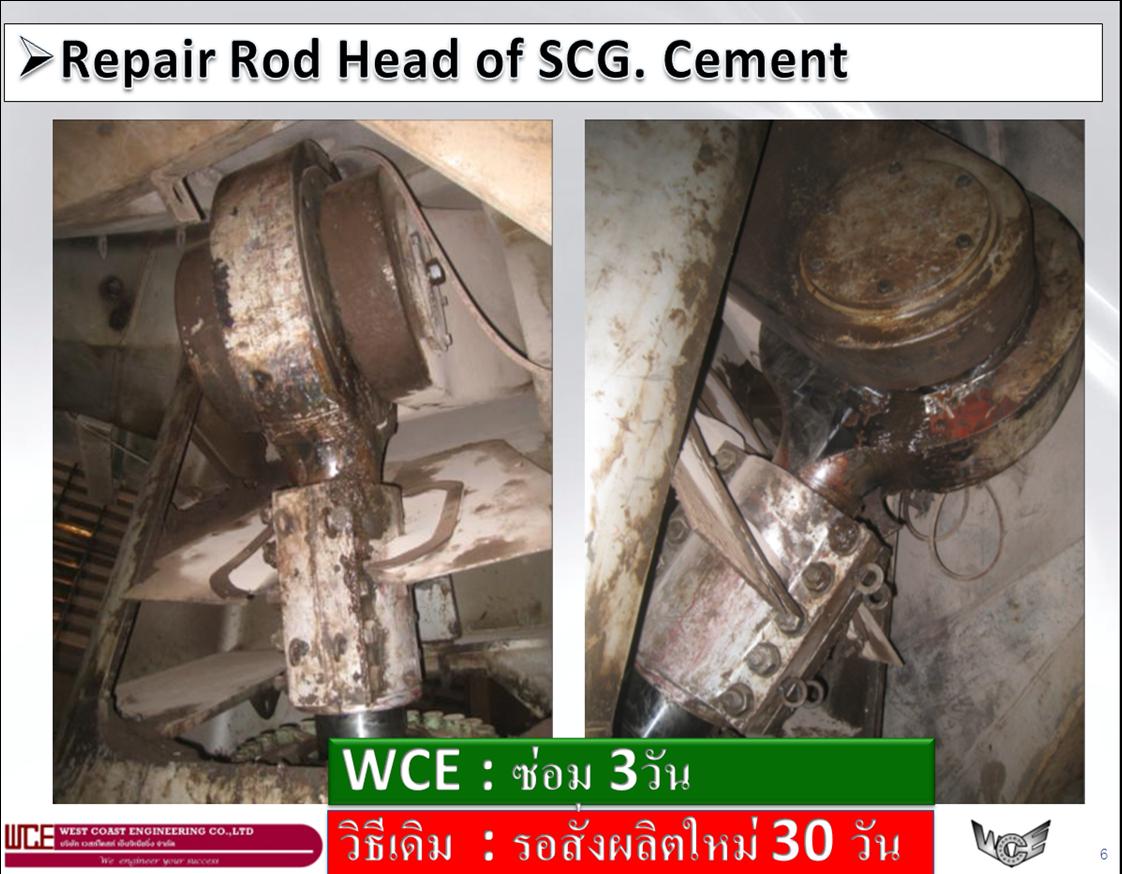

WCE has provided Head/Clevis repair service (Equipment in Clinker Production Line) to SCG Thung Song, helping to completely recover clinker production in 5 days, saving time instead of new production which takes up to 30 days. WCE is also entrusted to be the key engineering service center for SCG’s maintenance systems.

Mr. Kittisak Mapanaow, Managing Director of West Coast Engineering Company Limited or WCE, is one of the SSI groups. Revealed that for more than 10 years WCE has been committed to providing maintenance and engineering services. both customers of affiliated companies and other general customers by providing many types of workgroups such as Engineering and Project Services Repair and production of mechanical parts Maintenance service and skilled labor service work in the assembly of metal structures, etc. Recently, WCE received urgent repair work for SCG Thung Song to be able to return to normal operation. within a short time and complete production efficiency By having entered service to repair Head/Clevis (equipment in the cement production line) that is broken while in use, SCG does not have spare parts to replace, causing the production line to stop. analyze the problem and make repairs It took only 3 days for the repair to be delivered. As a result, SCG

Mr. Kittisak Disclosed more details of the work process. Until this success, There are the main working steps.

Repair inspection and design process Surface preparation for non-destructive inspection (NDT) including ultrasonic testing (UT) for internal defects, crack detection (PT) measuring the size and shape of the deformation from the center of the Workpieces with CMM Mobile (Coordinate Measuring Machine Mobile, measuring workpieces with complex shapes, large work with high resolution) and analyze the results of assessments compared to the workload that will be used. to design the repair process

repair process Start by heating (preheating) the workpiece in the oven for a specified time and then welding with E11018 wire, insulating the workpiece. and allow the workpiece to cool down slowly due to the need to accelerate the process, so use the stress relief method (Stress relieve) by vibrating with the Vibration Stress Relieve instead of baking it in a kiln. Then design the forming process to make the workpiece back to the desired size with a CNC Double Colum Machining Center (CNC milling machine) and CNC Vertical Lathe (CNC vertical lathe) and then grind it. Get the size and coordinates as specified in the form with various details until it’s done. Check the quality of the recording piece again. and then assembled Bearing (Bearing) by using Induction Heating (induction heater) to complete the repair process. Deliver the parts to SCG, which WCE has gained confidence from this repair service. both in quality

(E-SOS) of the company that was launched this year. And lead to the ability to produce parts to replace imports for various heavy industries for sure.

Contact Us

West Coast Engineering Company Limited (WCE)

🌐 www.wce.co.th

✉️ international@wce.co.th

📞 +66 (0) 2234-9889

Your Turn Key Engineering Solution

We engineer your sucCEss